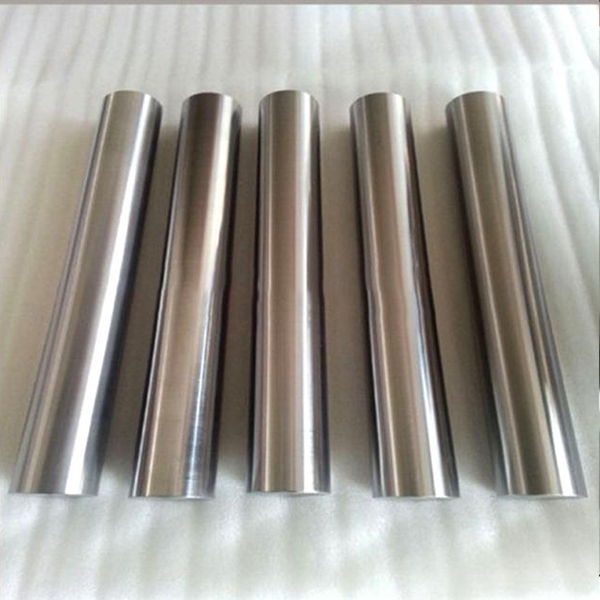

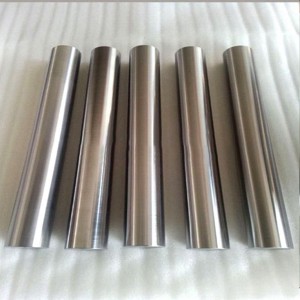

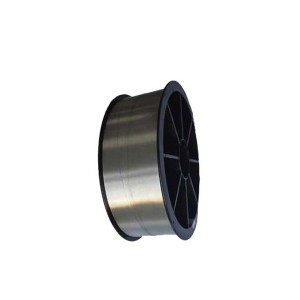

I-Astm B392 r04200 Uhlobo1 Nb1 99.95% Niobium Rod Pure Niobium Round Bar Price

Amapharamitha Omkhiqizo

| Igama lomkhiqizo | Ibha ye-ASTM B392 B393 High Purity Niobium Rod Niobium enentengo engcono kakhulu |

| Ubumsulwa | I-Nb ≥99.95% |

| Ibanga | R04200, R04210, R04251, R04261, Nb1, Nb2 |

| Okujwayelekile | I-ASTM B392 |

| Usayizi | Usayizi owenziwe ngokwezifiso |

| Indawo yokuncibilika | 2468 degrees centigrade |

| Indawo yokubilisa | 4742 degrees centigrade |

| Inzuzo | ♦ Ubuningi obuphansi kanye namandla aphezulu acacile ♦ Ukumelana okuhle kakhulu nokugqwala |

| ♦ Ukumelana okuhle nokushisa | |

| ♦ Ayinamandla futhi ayinabo ubuthi | |

| ♦ Iphuzu lokuncibilika eliphezulu, ukuvimbela ukugqwala okuhle, ukuhanjiswa okuphezulu kakhulu kanye nezinye izici ezihlukile. |

| Ukwakheka kwamakhemikhali (%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| I-Nb1 | Okusele | 0.004 | 0.002 | 0.002 | 0.004 | 0.004 | 0.002 | 0.07 | 0.015 | 0.005 | 0.0015 | 0.003 |

| I-Nb2 | Okusele | 0.02 | 0.02 | 0.005 | 0.02 | 0.02 | 0.005 | 0.15 | 0.03 | 0.01 | 0.0015 | 0.01 |

Ukubekezelelana Kwesilinganiso

| Ububanzi(mm) | Ukubekezelelana kobubanzi (mm) | Ubude (mm) | Ukubekezelela Ubude (mm) |

| 3.0-4.5 | ±0.05 | 200-1500 | +5 |

| >4.5-6.5 | ±0.10 | 200-1500 | |

| >6.5-10.0 | ±0.15 | 200-1500 | |

| >10-16 | ±0.20 | 200-2000 | |

| >16-18 | ±1.0 | 200-2000 | |

| >18-25 | ±1.5 | 200-2000 | |

| >25-40 | ±2.0 | 200-2000 | |

| >40-50 | ±2.50 | 200-2000 | |

| >50-65 | ±3.00 | 200-2000 | |

| >65-150 | ±4.00 | 200-1000 |

Isidingo Semishini (Isimo Esihlanganisiwe)

| Ibanga | Amandla okudonsa δbpsi (MPa), ≥ | Amandla okukhiqiza δ0.2, psi (MPa), ≥ | Ukwelulwa ngobude begeji obungu-1"/2", %, ≥ |

| I-RO4200-1 I-RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Isicelo

♦ Imboni ye-elekthronikhi, iKhemistri, i-Electronical, imboni yezemithi.

♦ Insimbi, i-Ceramics, i-Electronics, izimboni zamandla enuzi kanye nobuchwepheshe be-superconductor.

♦ Ama-ingot aqinile kakhulu, ahlanganisiwe kanye nama-alloying agents.

♦ Isetshenziswa kabanzi ekukhiqizeni izinhlobo ezahlukene zensimbi ye-alloy, i-alloy yokushisa okuphezulu, ingilazi ye-optical, ithuluzi lokusika, izinto zokuphatha i-superconducting kanye neminye imboni.

Bhala umlayezo wakho lapha bese uwuthumela kithi